Soluzione personalizzata per mini escavatori con benna a V e trapezoidale per scavo, livellamento e realizzazione di fossati

Descrizione del prodotto

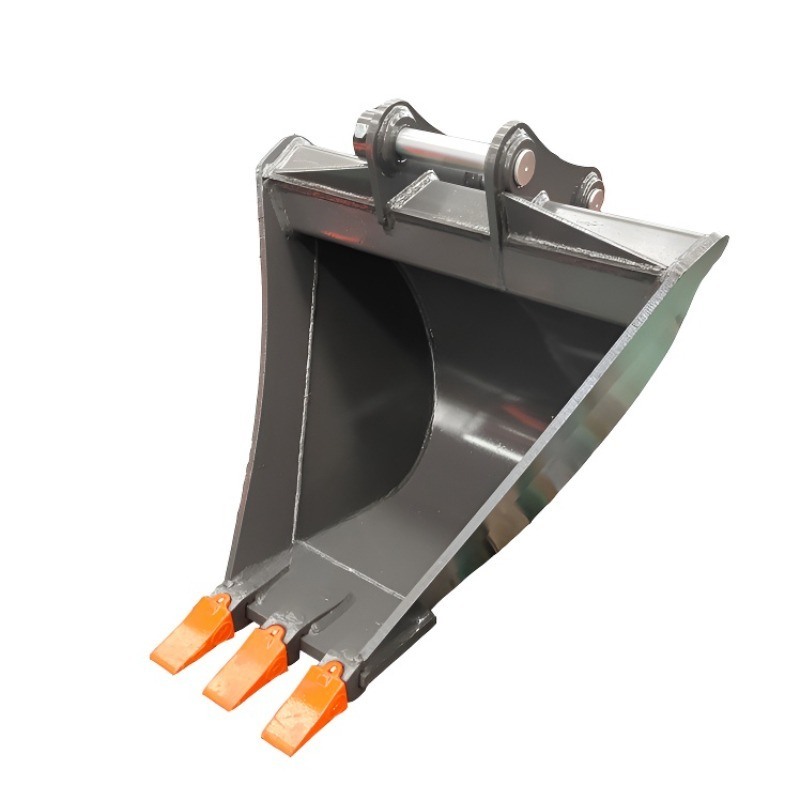

Potenzia i tuoi mini e speciali escavatori con le nostre benne a V e trapezoidali personalizzate, progettate per precisione, efficienza e durata in tutte le operazioni di movimento terra e paesaggistica. Le attrezzature standard spesso non sono sufficienti; offriamo soluzioni su misura che si integrano perfettamente con la tua macchina e massimizzano le prestazioni.

Le nostre benne a V eccellono nello scavo di fossati, trincee e posa di cavi, creando trincee pulite con fianchi inclinati e sprechi minimi, ideali per tubi, drenaggio o irrigazione. Costruite in acciaio ad alta resistenza come Q345B, NM400 o Hardox, resistono a condizioni difficili aumentando la produttività in cantiere.

Le benne trapezoidali offrono livellamento, inclinazione e finitura superiori per spalle stradali, modellatura del terreno e paesaggistica di precisione. Il loro design robusto garantisce un flusso di materiale regolare, una ridotta resistenza e una lunga durata, anche in ambienti esigenti.

Ogni benna è completamente personalizzabile in base al modello del tuo escavatore, alle dimensioni dei perni, alla larghezza del braccio e alle esigenze del lavoro. Regola la capacità, la larghezza, i denti o i taglienti; utilizziamo CAD avanzati per progetti su misura e supportiamo tutti i tipi di montaggio: a perno, attacchi rapidi o adattatori.

Prodotte sotto stretto controllo di qualità, le nostre benne sono tagliate a CNC, saldate a MIG/TIG in modo esperto e accuratamente ispezionate per l'integrità strutturale e la precisione prima della spedizione.

Offriamo anche logistica globale e supporto reattivo, garantendo che i tuoi accessori arrivino pronti per il lavoro. Contattaci oggi per un preventivo e sblocca tutto il potenziale del tuo escavatore.

| Parametro |

Descrizione |

| Peso escavatore adatto |

0,8–35 tonnellate (ad esempio, 0,8 t, 1 t, 1,2 t, 1,6 t, 2 t, 2,5 t, 3 t, 4 t, 5 t, 8 t, 9 t, 12 t, 15 t, 18 t, 20 t, 25 t, 30 t, 35 t) |

| Capacità benna |

0,11 m³ (esempio per escavatore da 1,2 tonnellate) a 21,19 piedi³ (per escavatore da 16–22 tonnellate) |

| Larghezza (Superiore) |

Personalizzabile, ad esempio, 900–2000 mm (35,43–78,74 pollici), tipicamente 300–1829 mm per vari modelli |

| Larghezza (Inferiore) |

Personalizzabile, comunemente la metà della larghezza superiore (ad esempio, 150 mm per 300 mm superiori), 200–813 mm (7,87–32 pollici) |

| Peso |

65–1429 kg (143–3150 libbre), a seconda delle dimensioni della benna e della classe della macchina |

| Materiale |

Acciaio T-1 per componenti critici/ad alta usura, HB400/450 per piastre antiusura e taglienti |

| Opzioni denti |

Denti standard del settore opzionali, vari marchi di qualità disponibili |

| Tagliente |

Tagliente HB450 (con o senza denti), tagliente temprato opzionale |

| Caratteristiche aggiuntive |

Cinghie antiusura per il rinforzo del fondo della benna, piastre laterali rastremate per ridurre l'usura e facilitare lo scarico, trave superiore a doppio raggio rigido con rinforzo interno |

| Applicazioni |

Lavori di drenaggio, scavo di fossati, profilatura di trincee, adatto per la conservazione dell'acqua, autostrade, agricoltura, condutture |

| Personalizzazione |

Adattato a larghezze superiori/inferiori specifiche, profondità e condizioni operative; disponibile in forme rettangolari, trapezoidali, triangolari |

| Compatibilità |

Adatto a vari modelli di mini escavatori (ad esempio, Airman, Bobcat, Case, Kobelco, CAT, New Holland, Daewoo) con configurazioni di perni personalizzate |

| Garanzia |

1 anno (esempio da BONOVO) |

| Note speciali |

Non progettato per aree rocciose con eccessivo sollevamento; può essere utilizzato con rotatori inclinabili per una maggiore precisione |

D: Perché dovrei acquistare da voi invece che da altri fornitori?

R: Operiamo con due società e una fabbrica, consentendoci di offrire prezzi competitivi e qualità superiore. Il nostro team vanta oltre 20 anni di esperienza nel settore dei macchinari, garantendo prodotti e servizi affidabili.

D: Quanto tempo impiega la consegna?

R: Per gli articoli in stock, la consegna richiede in genere 10 giorni. Per gli articoli non in stock, varia da 20 a 30 giorni. Gli ordini personalizzati avranno tempi di consegna confermati in base ai dettagli specifici dell'ordine.

D: E il controllo qualità?

R: Utilizziamo attrezzature di collaudo avanzate e personale qualificato per ispezionare ogni articolo per la garanzia della qualità. Verifichiamo anche la quantità corretta prima della spedizione per garantire l'accuratezza.

D: Quali sono i vostri termini di pagamento?

R: Accettiamo T/T, L/C, Western Union e altri metodi. Valute accettate: USD, EUR, RMB. Per ordini ≤1.000 USD: pagamento anticipato del 100%. Per ordini ≥1.000 USD: 30% T/T in anticipo, con il saldo dovuto prima della spedizione.

D: Come faccio a effettuare un ordine?

R: Forniscici il modello della macchina, il nome del pezzo, il numero del pezzo e la quantità per ogni articolo. Ti invieremo prontamente un preventivo professionale.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!